Dynamic fill quantity control

Highest reliability in vaccine production thanks to checkweigher

Key facts

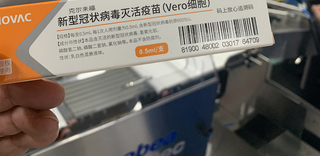

Directly after the approval for their developed vaccine CoronaVac, the manufacturer Sinovac faced the challenge of ensuring a large production volume. This also included complete control of fill quantities.

Application & Product

A dynamic weighing solution at the end of the packaging line ensures that the vaccine doses and that package inserts are included.

Customer benefits

- High output up to 260 pieces/min

- Easy cleaning of the system

- Rejection monitoring to ensure correct discharge

- Flexible design facilitates integration into the packaging line

"Our Minebea Intec checkweighers play an important role in our quality assurance. They meet our special requirement on accuracy, throughput and any other aspects."

Jianan Chen

Packaging Workshop Manager at Sinovac Biotech Ltd.

When biopharmaceutical company Sinovac received the Phase III clinical trial results of the vaccine and submitted the launch report to the China National Medical Products Administration, it immediately began planning the production line for CoronaVac. Minebea Intec was called in to provide design-in support in the product inspection area. With high performance and environmental conditions in mind, Minebea Intec’s experts conducted tests on the customer’s products and adjusted parameters to provide optimized solutions even before production began.

The Synus checkweigher rejects the vaccine dose after packaging if the package insert or the vaccine dose are missing. The lower rejection weight is defined as 0.5 g of the final product at a rate of 260 pieces per minute. The defective product packages are discharged into a sealed transparent rejection container. To ensure that inspected defective parts have actually been rejected, another sensor has been installed after rejection to trigger an audible alarm if non-rejected defective parts pass over the belt.

Thanks to the flexible design of the Synus checkweigher, the height of the conveyor belt could be adjusted. This made integration much easier. This high degree of flexibility proves particularly advantageous when the complete design of the production line has not yet been finalized. For this case - and for convenient later line changes - Synus can be flexibly adapted to working heights of 600 - 1100 cm.

Mediacenter

| Category | File Name | File Size | File Type | ||

|---|---|---|---|---|---|

| Best Practices | |||||

| Best Practices | Best Practice // Minebea Intec’s checkweigher proves highest reliability in vaccine production | 865 KB | |||